“Field Decontamination Studies with Chemical Warfare Decontaminating Solution DS2,” G. H. FIELDING Protective Chemistry Branch Chemistry Division, NRL Report 6191,U.S. NAVAL RESEARCH LABORATORY Washington, D.C.

In 1964, the Navy decided to test its new cleaning agent DS2 to compare it to “DANC” which was used in all Navy Bases as a cleaner ashore. Treasure Island Damage Control school was chosen at the site because they regularly train in radiological, chemical and biological decontamination on two week intervals since 1948. Up until 1970 the decontamination area was located on the northwest corner of the island which contained a mock up of a ship (the first USS Pandemonium), a mock up of an airplane, and a 5 inch gun which was used for general training and for decontamination. In 1970 they tore down the first USS Pandemonium and built housing over the site and rebuilt it to the Northeastern side of the Island. The fire fighting school which was a separate location and was also replaced to be further to the north east of the island in 1988.

Also it should be noted that Treasure Island was designed to train instructors in how to conduct training on their ships and bases so the contamination must be checked for every military base in the world. https://treasureislandcalifornia.wordpress.com/2021/01/31/ti-graduates-of-abc-school-went-on-to-train-their-shipmates-uss-macon/ Here is a map of their facilities including the CHEMICAL WARFARE SCHOOL – Building 269

The standard U.S. Army chemical warfare decontaminant DS2 has been studied for shipboard applicability. Experimentation was conducted by staff personnel of the ABC School, Treasure Island, California. Single and multiple treatments of DS2 and DANC were compared with water washdown plus aeration in effectiveness against mustard gas absorbed in Navy paint. Residual mustard gas in paint was evaluated via the vapor source strength, as determined by the NRL Vaporator and the MI 5 CW Agent Detector kit. When all treatments were preceded by thorough washdown, single treatments with DS2 or DANC were two to four times as effective as simple aeration. Multiple applications of DS2 were of very limited value. p. ii. Field Decontamination Studies with Chemical Warfare Decontaminating Solution D52 https://apps.dtic.mil/dtic/tr/fulltext/u2/612665.pdf

I will place links to TI locations that were published in 1988 with maps at a link here once I write those posts.

Here is an aerial photograph of the first USS Pandemonium and you can see the airplane and another spot which would be the 5 inch gun.

FORMER NAVAL STATION TREASURE ISLAND, SAN FRANCISCO, CALIFORNIA

February 2006, p 8-24

notice Alcatraz in the background and the headlands

Google Map of the view of Alcatraz from this position Note that ABC Warfare Defense published in 1960 and 1963 shows the training on Treasure Island.

The Chemicals used in DANC and DS2 are far more deadly than Mustard Gas.

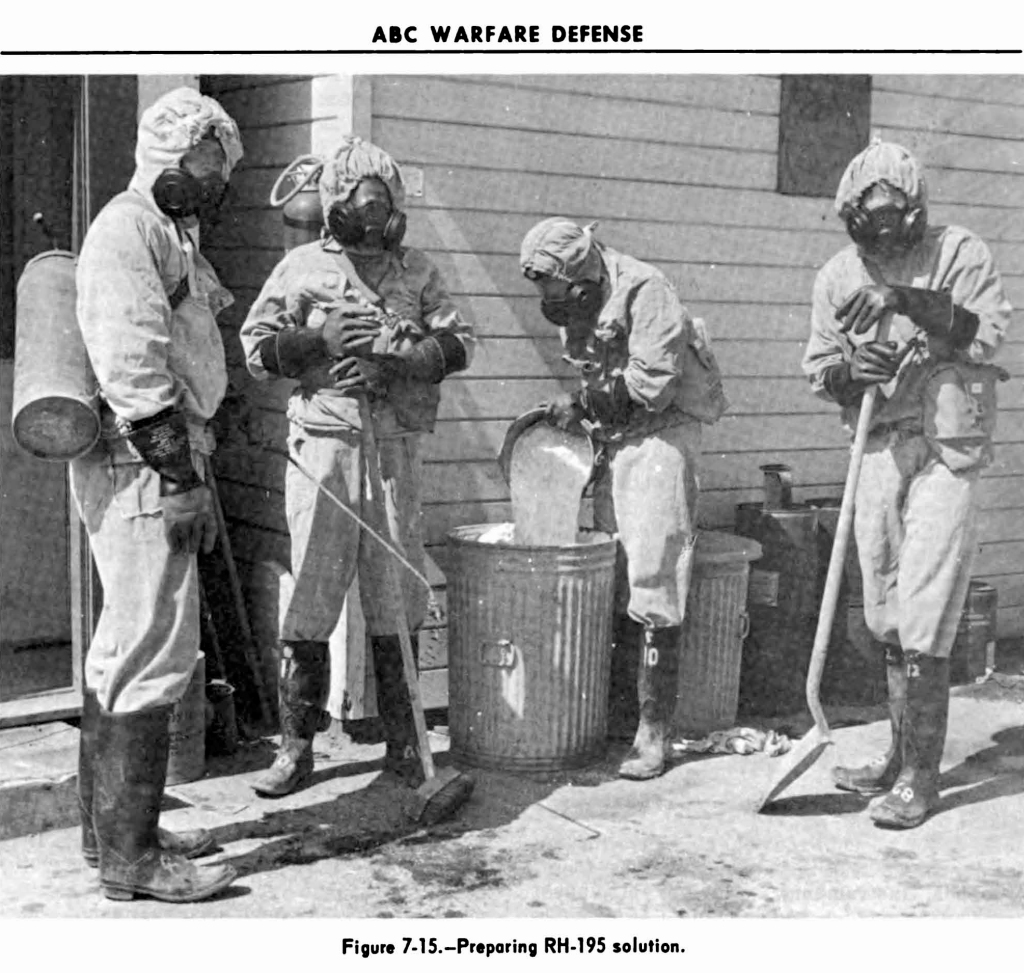

To prepare the decontaminating solution, RH-195 powder is dissolved in the tetrachlorethane in the proportion of one pound of RH195 to ten pounds of solvent (fig. 7-15). In measuring the parts by volume, use one jar (5 gallons or approximately 25 pounds) of powder to four drums (20 gallons) of the solvent. Smaller quantities are prepared in the same proportion; that is, one volume of powder to four volumes of solvent.

DANC

Danc, the Navy’s decontaminating solution was prepared by mixing RH-195 powder (chlorine) dissolved in the tetrachloroethane in the proportion of one pound of RH195 to ten pounds of solvent (fig. 7-15). In measuring the parts by volume, use one jar (5 gallons or approximately 25 pounds) of powder to four drums (20 gallons) of the solvent. Smaller quantities are prepared in the same proportion; that is, one volume of powder to four volumes of solvent. p 129 ABC Warfare Training 1960.

Tetrachloroethane is toxic at parts per million, here the Navy is using it in enormous quantities. EPA fact sheet: https://www.epa.gov/sites/production/files/2016-09/documents/1-1-2-2-tetrachloroethane.pdf

RH 195 is a highly concentrated form of Chlorine – EPA fact sheet: https://www.epa.gov/sites/production/files/2016-09/documents/chlorine.pdf

The Bleach content is 13 times that of household bleach, see The Army’s procurement and management of decontamination solution no. 2 : implications for hazardous waste reduction : hearing before the Environment, Energy, and Natural Resources Subcommittee of the Committee on Government Operations, House of Representatives, One Hundred First Congress, second session, June 28, 1990 attended by Barbara Boxer and Nancy Pelosi

DANC, a rapid decontaminating agent for use against all common blister agents, is limited to use ashore. This agent is stable in storage and is less corrosive than bleach, but the vapor hazard during its use, and possibly in storage, is a serious drawback. It is a white- to cream-colored powder which releases active chlorine on contact with the blister gases and thereby neutralizes them. Weapons, instruments, vehicles, airplanes, and metal surfaces and equipment of all kinds can be decontaminated with it. Prior to use, the powder is dissolved in tetrachlorethane, sometimes called TCE.

To prepare the decontaminating solution, RH-195 powder is dissolved in the tetrachlorethane in the porportion of one pound of RH195 to ten pounds of solvent (fig. 7-15). In measuring the parts by volume, use one jar (5 gallons or approximately 25 pounds) of powder to four drums (20 gallons) of the solvent. Smaller quantities are prepared in the same proportion; that is, one volume of powder to four volumes of solvent.

The solvent, tetrachlorethane, is stable and not flammable, but it is poisonous in both the liquid and vapor states. Continued breathing of the vapors or absorption of the liquid through the skin may result in serious injury to personnel, as it produces a poisonous effect on the body which becomes progressively more severe. A strong concentration of the fumes may cause unconsciousness and death. Hence, workers with the solvent or the solution must exercise care in handling the material and should be adequately protected. If mixing woud involve unavoidable breathing of vapor, protective masks should be worn. The hands should be protected with rubber gloves, but care should be taken not to wet the gloves unnecessarily since the solution will damage them on prolonged contact. Personnel should be instructed to remove promptly any articles of clothing which become soaked with the liquid and to wash the skin with soap and water as soon as possible.

The solution may be prepared in any DRY metal or wooden container preferably in the open. Operators should stand to the windward to avoid contact with the vapors. A wooden paddle should be used to stir the mixture and to insure that the powder is completely dissolved. The solution breaks up in storage and should not be stored for more than three months.

One gallon of solution in the above proportions will effectively decontaminate six square yards of very heavily contaminated surface, 15 square yards of heavily contaminated surface, 30 square yards of moderately contaminated area, and an even larger area of light contamination. The solution is exceedingly destructive to rubber and plastics if allowed to remain in contact with them. It is somewhat corrosive, and what is left after the solution evaporates should be flushed from the surface which has been decontaminated. Surfaces which are easily corroded should be given a coat of oil after decontamination has been completed. p 139 ABC Warfare 1960

RH 195 is Chlorine

Tetrachloroethane is toxic at parts per million, here the Navy is using it in enormous quantities. EPA fact sheet: https://www.epa.gov/sites/production/files/2016-09/documents/1-1-2-2-tetrachloroethane.pdf

TCE is used today to designate trichloroethylene which is also a hazardous chemical where in Silicon Valley the Deed Restrictions to prevent human exposure include no housing, no schools for anyone under the age of 21, no daycare, no elderly care, its really bad stuff! https://www.epa.gov/assessing-and-managing-chemicals-under-tsca/final-risk-evaluation-trichloroethylene

Considering that DANC WAS USED IN EVERY NAVY BASE then ALL Navy bases cannot be used for housing and anyone under the age of 21 should not be near any former Navy Base! This includes Hunters Point Shipyard, Concord Naval Weapons Station, Marae Island, etc.

DS2

The chemicals listed below are dangerous in parts per million, but the Navy made batches of this stuff in 25 gallon quantities. Links to the GAO, OSHA, NIH and CDC are provided for each chemical below. The Navy used this on all bases until 1986.

THE GAO issued this report on why the Army should stop using DS2: “DOD Should Eliminate DS2 From Its Inventory of Decontaminants April 1990”

https://www.gao.gov/assets/150/149202.pdf

“A candidate for a limited-service shipboard CW decontaminant is the U.S. Army’s DS2 (Decontaminating Solution No. 2) (Ref. 1). This liquid material is a mixture of

70 Percent Diethylenetriamine (DETA

28-percent methyl Cellosolve

2-percent sodium hydroxide by weight, also known as Lye or Caustic Soda.

70-percent diethylenetriamine (DETA) OSHA site:

1.1.2. Toxic effects (This section is for information only and should not be used as the basis of OSHA policy.)

In general, the vapors of these amines are painful and irritating to the eyes, nose, throat, and respiratory system. The liquids can cause severe damage to the eye and serious burns to the skin. Hypersensitivity can be produced in some people which results in contact dermatitis or an asthmatic respiratory response, or both. The LD50 values for white rats for a single oral dose are 1.2, 1.4, and 2.5 g/kg body weight for EDA, DETA, and TETA respectively. (Ref. 5.5)

There is currently an OSHA PEL of 10 ppm for EDA. There have been no PEL values yet set for DETA and TETA. ACGIH has adopted a TLV of 10 ppm for EDA and 1 ppm for DETA.

28-percent methyl Cellosolve –

CDC Site on Cellosolve –

Human data: Chronic exposure to 50 to 100 ppm has been associated with headache, dizziness, lethargy, weakness, hyperreflexia, disorientation, unequal pupil size, and visual and/or auditory disturbances [ACGIH 1991]. It has been reported that 3,380 mg/kg is the lethal oral dose [Young and Woolner 1946]. [Note: An oral dose of 3,380 mg/kg is equivalent to a 70-kg worker being exposed to about 50,000 ppm for 30 minutes, assuming a breathing rate of 50 liters per minute and 100% absorption.]

2-percent sodium hydroxide by weight.

OSHA Article – Sodium hydroxide (NaOH) is a an odorless, white crystalline solid that absorbs moisture from the air. Sodium hydroxide is very corrosive. It can cause irritation to the eyes, skin, and mucous membrane; an allergic reaction; eye and skin burns; and temporary loss of hair. Workers may be harmed from exposure to sodium hydroxide. The level of harm depends upon the dose, duration, and work being done.

The Navy report continues on testing DS2 and DANC at Treasure Island CA:

Certain engineering tests of DS2 and a related spray applicator, the E17R1 Decontaminating Apparatus, are covered by a Dugway Proving Ground Report (2). No data exist on the effectiveness of DS2 in shipboard environments, and the application techniques best adapted to shipboard use. Some factors which sharply distinguish the shipboard decontamination problem from that ashore are: (a) the general use on navy ships of paints which are more sensitive to solvents than the paints common to shore or aircraft applications, and (b) the availability of essentially unlimited amounts of water, via the shipboard washdown systems and firehoses, for use in decontamination.

The preliminary trials in the evaluation of DS2 at Treasure Island were designed in 9 parts to compare the decontamination effectiveness of DS2 with an obsolete but effective decontaminant DANC, whose performance in a navy environment is well known (3). In addition, the preliminary trials were intended to explore some variations in the methods by which DS2 might be used at sea.

DANC (Decontaminating Agent, Non Corrosive) is a 1 to 15 solution (by weight) of an active-chlorine compound dichlorodimethylhydantoin (RH 195) in the solvent tetrachlorothane (TCE). While effective against mustard gas and the V agents, DANC fails to neutralize G agents; corrodes metals in contact with moisture; and swells and damages paints, rubbers, and plastics. Inhalation of the vapor of TCE or absorption of the liquid through the skin has the characteristic toxic effects of chlorinated solvents. Recognition of these undesirable properties after World War II caused the Navy to discard DANC for shipboard use.

Many of the physico-chemical properties of DS2 are in contrast with those of DANC. DS2 has about four times the viscosity of DANC, so that it drains more slowly from vertical surfaces, and leaves a thicker film. DS2 is also essentially nonevaporating. These two properties would appear to extend the active lifetime of DS2, on a contaminated vertical surface, well beyond that of DANC. However, the chemical reaction between DS2 and mustard gas is inherently slower than the DANC and mustard gas reaction. Moreover, three side reactions between components of DS2 and the atmosphere act gradually to reduce decontamination effectiveness. These are (a) the reaction of atmospheric carbon dioxide with DS2’s sodium hydroxide to form sodium carbonate; (b) the reaction of carbon dioxide with the amine DETA, which comprises 70 percent of DS2, to form a solid amine carbonate; and (c) the absorption of water.

The net effect of these complexities could not be predicted and operational tests were

required for useful evaluation.”

The Testing

The Navy set up steel plates in a vertical position to mimic a wall of steel ship, painted just like the paint on ships and conducted tests at various combinations of chemicals in order to see what effect it would have to clean the mustard gas and maintain the paint on the ship. Very quickly they realized that both DANC and DS2 removed the paint.

Later they conducted tests on the 5 inch gun and in this picture you can see the first USS Pandemonium in the background.

“FINAL TRIALS

General

On the basis of the preliminary trials, additional experiments were designed by representatives of the ABC school, the Bureau of Ships, and this Laboratory. These were carried out entirely by personnel of the ABC school after the Bureau of Ships and NRL personnel had returned to Washington.

The improvements desired to be introduced into the experimental conditions of the final trials were: (a) conduct of all trials simultaneously to obtain uniformity of wind and temperature, (b) use of representatively well-aged paint surfaces, (c) addition of an aeration-only trial, (d) use of a paint removed as a decontaminant, (e) prehosing* of all test surfaces after application of mustard, (f) duplication of Vaporator tests, and (g) measurement of the vapor source strengths of decontaminated surfaces for extended periods following decontamination treatments.

The surface chosen for the final trials was the forward shield of a 5-inch gun located on the grounds of the ABC school (Fig. 8). The shield was inclined 45 degrees from the vertical, and faced approximately west and toward the prevailing winds. The navy 5H paint on the gun shield was well-aged and heavy (28 to 34 mils). An extremely useful feature of the shield was a series of reinforcing ribs, about 2-inches high, welded perpendicularly to the surface of the shield. In this way, a series of eight separate but identical test surfaces was provided, each about 14-inches square. These panels were assigned numbers which read from left to right, facing the panels. “Page 14, Field Decontamination Studies with Chemical Warfare Decontaminating Solution D52

The gun mount is shown in Fig. 8.” Page 15, Field Decontamination Studies with Chemical Warfare Decontaminating Solution D52 https://apps.dtic.mil/dtic/tr/fulltext/u2/612665.pdf

13 thoughts on “TI-The Smoking Gun – Chemical Warfare test at Treasure Island Navy evaluates methods use to clean up Mustard Gas”